Expertise

Activated carbon

In a broad sense Activated Carbon is amorphous, carbonaceous material having well-developed internal surface and is usually characterized by a poly disperse porous structure consisting of pores of different shapes and sizes. This makes carbon with high surface area open up for adsorption of molecules, atoms or ions from surroundings. Environ activated carbon fabric is made from patented technology wherein the raw material viscose rayon is pre treated, dried, carbonized and activated. The properties of the activated carbon products are further enhanced by impregnating with value added technologies such as anti-bacterial, anti-fungal, anti-oxidant, anti-allergen, and patented herbal extracts.

-

- Very low ash content

- Acid and alkali resistant

- Better electrical conductivity

- Better chemical stability

- Easy regeneration

- Best heat insulator

- Good tensile strength

- High surface area

- Higher adsorption capacity

- ACF is widely recognized as a versatile material that has potential to act as a novel adsorbent, catalyst as well as support to catalyst.

- ACF is a carbon material that absorbs odor from air or impurities from liquids because it provides an extremely high adsorption/desorption speed compared with powdered or granular activated carbon, ACF is extensively used in the field of air and water purification such as harmful gas removal or the recovery of Freon.

- ACF is a pure and third form of activated carbon. It is soft and light weight and has a higher specific surface area, large pore volume, lower pressure drop, and heat resistance, very fast adsorption and desorption characteristics.

- Recently, new types that efficiently remove the chemical pollutants (Acetaldehyde and Formaldehyde have been added to the product lineup which leads to even greater demand.

- We have been preparing ACF from the commercially obtained raw (non-carbonized and non-activated) carbonaceous fabrics based on viscose rayon and phenolic resin precursors.

- The Surface Area of our ACF is 1200-1400 m2 /gm and iodine value is 1100-1300 mg/gm

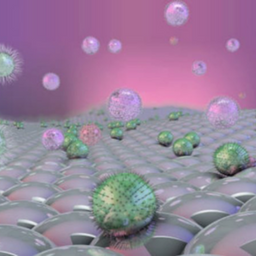

- Nano silver activated carbon fabric has long been used in purification processes for indoor air quality. However, the bio aerosol removal by activated carbon is not often sufficient to be used in an air control devise. In order to overcome these problems, silver nano-particles have been proposed as an antibacterial and antiviral agent on the surface of activated carbon. This filter can be an effective method to control bioaerosol and improve indoor air quality.

- Silver has been used for the treatment of medical ailments for over 100 years due to its natural antibacterial, antiviral and antifungal properties. They have extremely large relatively surface area, increasing their contact with bacteria, virus or fungi and vastly improving its bactericidal, virucidal and fungicidal effectiveness.

- The nano silver when in contact with air-borne bacteria, virus and fungus will adversely affect cellular metabolism and inhibit cell growth. The nano silver suppresses respiration, basal metabolism of electron transfer system, and transport of substrate in the microbial cell membrane. The nano silver inhibits multiplication and growth of those bacteria, virus and fungi which cause infection, odour, itchiness and sores.

- Nano Silver fabric can be applied to range of other healthcare products such as dressings for burns, scald, skin donor and recipient sites; acne and cavity wounds; and female hygiene products – panty liners, sanitary towels, pants and so on.

-

- Kitchen exhaust filter

- Air coolers filter

- Car cabin filter

- Deodorizers

- Oil filters

- Sound insulation

-

- Fire blanket

- Kitchen exhaust

- Water cartridge

- Air-conditioner filter

- Deodorizers

-

- Granular activated carbon has a relatively larger particle size compare to powdered activated carbon and consequently, presents a smaller external surface.

- Granulated carbon are used for water treatment, deodorization and separation of components of flow system. GAC can be either in granular form or extruded form.

- GAC is designated by sizes such as 8X20, 20X40 or 8X30 for liquid phase applications and 4X6, 4X8 or 4X10 for vapour phase applications.

-

- Shoe-insoles

- Respirator masks

- HEPA filters

- Water cartridge

Expertise

Plasma Technology

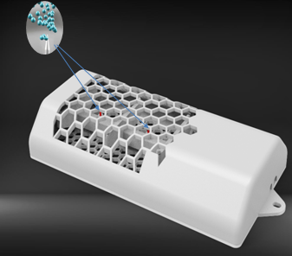

Plasma Air uses bipolar ionization technology to proactively purify indoor air at the source of contamination. Plasma Air technology produces a natural bio-climate rich in positive and negative oxygen ions. The negative ions contain an extra electron while the positive ions are missing an electron resulting in an unstable condition. In an effort to restabilize, these bipolar ions seek out atoms and molecules in the air to trade electrons with, effectively neutralizing particulate matter, bacteria and virus cells, odorous gases and aerosols, and VOCs.

- Plasma Shield with unique air purification technology helps in removing Viruses, bacteria, VOC and other airborne particles from the air and hence makes it healthier for breathing.

- It’s unique design with patented technology is highly efficient.

- Optional LED function is available for display on panel.

- It is a retrofitted solution hence no hardware change is required for the installation*.

- Low Cost over competition is the key advantage.

- Made in India

- Patented Technology

Expertise

Coatings

A coating is a covering that is applied to the surface of an object, usually referred to as the substrate. The purpose of applying the coating may be decorative, functional, or both. Here we are using this technology on a wide range of substrates to produce various properties such as:

- Anti-viral

- Anti-bacterial

- Anti-fungal

- Anti-algae

- Anti-corrosion

Expertise

Green Chemistry

Green chemistry is the design of chemical products and processes that reduce or eliminate the generation of hazardous substances. It reduces pollution at its source by minimizing or eliminating the hazards of chemical feedstocks, reagents, solvents, and products. It mainly focuses on the environmental impact of chemistry, including reducing consumption of non-renewable resources and technological approaches for preventing pollution. Here we are developing different properties using green chemistry with respect to:

Expertise

Injection Moulding

In-house Injection Molding machines available for plastic ancillary items for filter casings and molded filters and other plastic processed parts using various different polymers like PP,PC, ABS etc.

Expertise

Impregnation

Impregnation is the classic and the simplest procedure to load a given porous support with the metal component in the solid-state way or more commonly via wet impregnation. It is the process of removing air from pores of the substrate surface and replacing the same to obtain desired properties.

Expertise

Flexible Corrugated Drain Pipe

Our corrugated pipes are basically plastic pipes having a series of ridges and grooves running parallel to each other on its surface. The ridges and grooves follow a pattern that is perpendicular to the centre line of the pipe and bisecting the same as well. Our corrugated pipes are made of poly ethylene (PE)/ polyvinyl chloride (PVC)/ high-density polyethylene (HDPE).

Corrugated pipes are used where flexibility is an important factor rather than strength and durability, their flexibility makes them more useful and suitable for a wide variety of uses compared to rigid and non-corrugated pipes. Our corrugate pipes are perfectly suitable for drain and hose pipes of Air conditioners, refrigerators, washing machine etc.

Expertise

Filter Mesh

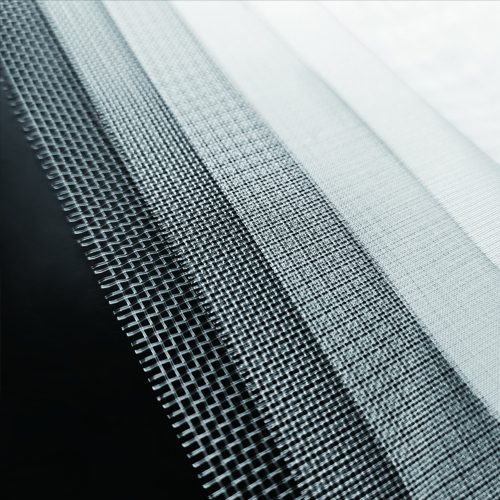

Filter Mesh is made of mono-filaments of PP, PET, NYLON(PA-66) (1:1 weaving method, plain weave), which is ideal for filtering most liquid particulates, air particulates etc.The term mono filament means that each thread used in the construction of the cloth is a single smooth solid strand instead of many smaller diameter threads twisted together, as in a spun or multi-filament material. These mono-filament threads are perfectly round in section and are extruded to very precise and uniform diameters.

Their advantages are:

a) due to their uniformity they can be woven with great precision to give exact and regular apertures,

b) the resulting material has a very smooth surface so that the filtered particles will easily separate from it,

c) they have great strength and elasticity.

After weaving, our fabrics undergo a finishing process to add the properties required for specific applications. During the finishing process, the fabric is washed and dried to remove any impurities and the yarns are then heat set for proper inspection.

Plastic Molded Filter parts:

Environ Care has state of the art injection molding machines to provide end customers plastic molded parts inserted with filter meshes.

Application:

1. Air Conditioner Filters

2. Automotive Filters

3. Oil Filters

4. Solvent Filters

5.Medical Filters